Ball Mill Manufacturer

High Quality Ball Mill Machineries

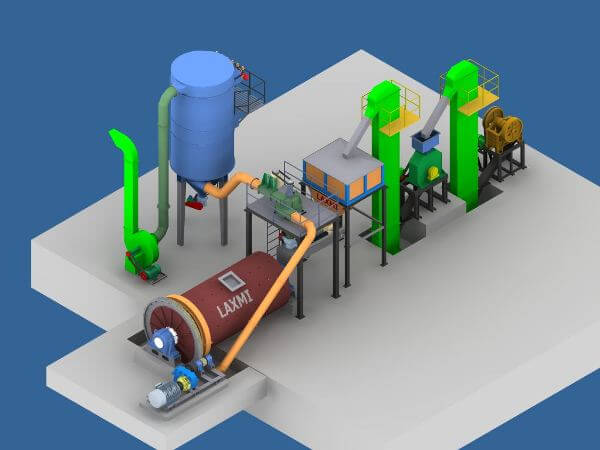

We strive hard to contribute substantially to the global priority areas of energy conservation and environment protection. For saving energy and achieving good quality products, we have developed a BALL MILL with Classifier Unit.

The whole unit consists of equipments such as; Jaw Crusher, Hammer mill, Elevator, Storage Hopper, screw Feeder, Ball Mill, Classifier. RPJ Dust Collector, Air Locks and Blower.

OPERATION

The above unit is used for grinding of Dolomite and Calcite. Jaw Crusher crushes the stone to the size up to 12 mm which is lifted by the Elevator and discharged in hammer mill. Hammer mill reduce the product to-3mmand there is into Storage Hopper. From Hopper a Screw Feeder is provided with a Variable Frequency Drive to control the Feed of crushed material to Ball Mill. The Ball Mill is having a Manganese Steel Lining and steel grinding media which-grind the material into fine powder. This powder is discharged through periphery of the Ball Mill.

The Ball Mill moves with suitable spherical roller bearing with Plummer block and a Girth Gear which is driven by Helical Gear Box through Fluid Coupling and Electric Motor.

A Blower is provided in the system which sucks the powder discharged from Ball Mill and it goes to LAX Classifier which classifies the fine particles i.e. (20 Micron or 15 Micron 10 Micron) and coarse material is returned to Ball Mill for re-grinding. After being classified, the material goes to RPJ Dust Collector where we collect the required product through Air Lock.

TECHNICAL SPECIFICATIONS

Power requirement:

Details of power requirement and other allied equipment beings an integral part of the Ball mill are furnished as under:

- Jaw crusher 10 HP/1440 RPM/TEFC/Sq. Cage Motor

- Bucket Elevator 03 HP/1440 RPM/TEFC/Sq. Cage Motor

- Hammer Mill 25 HP/1440 RPM/TEFC/Sq. Cage Motor

- Bucket Elevator 03 HP/1440 RPM/TEFC/Sq. Cage Motor

- Screw Feeder 02 HP/1440 RPM/TEFC/Sq. Cage Motor

- Ball Mill 150 HP/1440 RPM/TEFC/Sq. Cage Motor

- Classifier 25 HP/1440 RPM/TEFC/Sq. Cage Motor

- Blower 60 HP/1440 RPM/TEFC/Sq. Cage Motor

- Air Locks (3 No.) 02 HP/1440 RPM/TEFC/Sq. Cage Motor

- D97 - 20 microns – 1000 Kgs. / Hour

- D97 - 15 microns - 850 Kgs. / Hour

- D97 - 10 Microns - 650 Kgs. / Hour (The above production data is on tentative basis which may vary as it depends upon the hardness and grind-ability behavior of the material and the same may not be deemed as firm figures)

- LENGTH 15 METERS

- WIDTH 10 METERS

- HEIGHT 6.25 METERS