Micronizing Plant Manufacturer

High Quality micronizing plant Machineries

SEEMA ENGINEERING WORKS is well recognized for its quality products in the field of minerals grinding machines and always keeping pace with the modern technology.Although our machines were giving maximum 500 mesh size powder production, looking to the present market scenario where there is need of 20 and 10 micron size Product as well as, we Have developed MICRINIZING PLANT to fulfill the present requirement of our Customers.

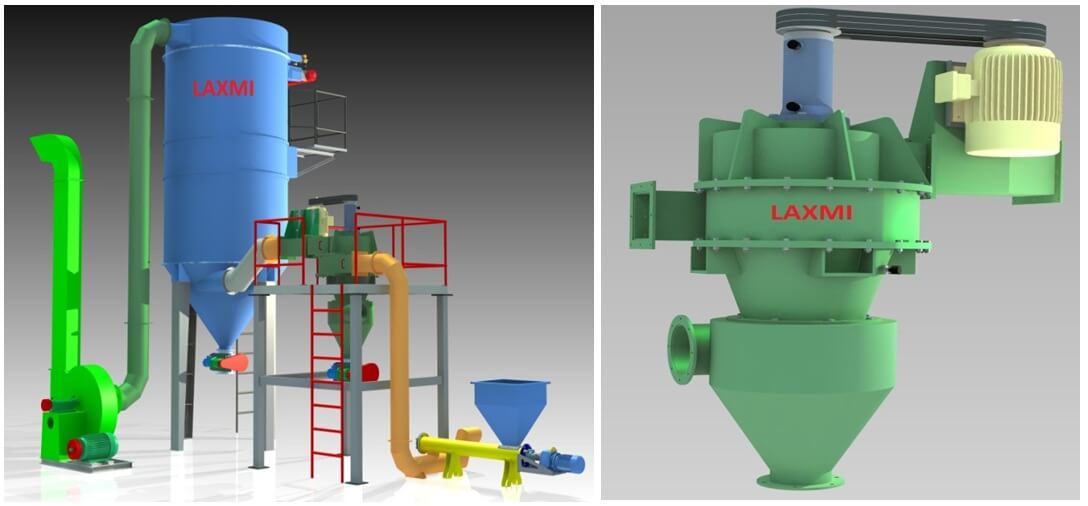

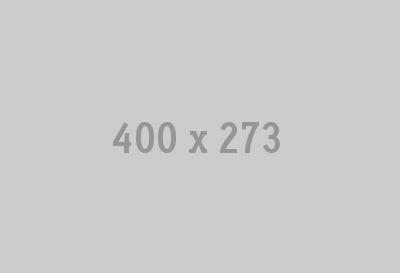

Our Micronizing plant consists of feed hopper with screw feeder, Ultra fine air classifier (LAX),inter-connecting Ducts, RPJ Dust Collector (Bag Filter), Blower, Air Compressor and Electric Control Panel with Electric Motors.

OPERATION

This unit has specially been designed to serve the purpose of classification of the ground material. The mineral powder of 400/500 mesh size is feed to the hopper through screw feeder which further leads to the classifier unit which classifies the powder in the order of 20 or 10 micron size and the coarse material (i.e. Tailing) is recovered from the bottom of the Air lock. The classifier runs through ‘V’ Belts drive with the help of Electric Motor. The RPM of the classifier is adjusted through variable frequency drive in order to obtain different microne sizes. The Blower Placed in the circuit pushes the material to the classifier unit for classification of the material as per requirement and then the same goes to the RPJ Dust Collector from where the final product is collector through Air Lock. It is a Continuous process wherein we feed new material with tailing material through screw feeder.

| SPACE REQUIRED FOR THE PLANT | LENGTHUpto 9 METERS | WIDTH Upto 6 METERS | HEIGHT Upto 7METERS |